|

Prepping for the Family Boat Build As you saw in the last series, the Siletz Tribal Charitable Contribution Fund awarded us $1800 to conduct a Family Boat Build during Christmas Break, December 26-30 this year. Now that we have the money, it's time to get cracking. Step 1 was to get the wood. I called Mike at Crosscut in Eugene and arranged for 1/2" and 1/4" Okume plywood to be set aside. On Thursday, I did a 153 mile circuit to Salem to Eugene to Toledo. Curt and Jim were there, where they'd been oiling the Winterhawk. Now it was time to turn to on the Family Boat Build.

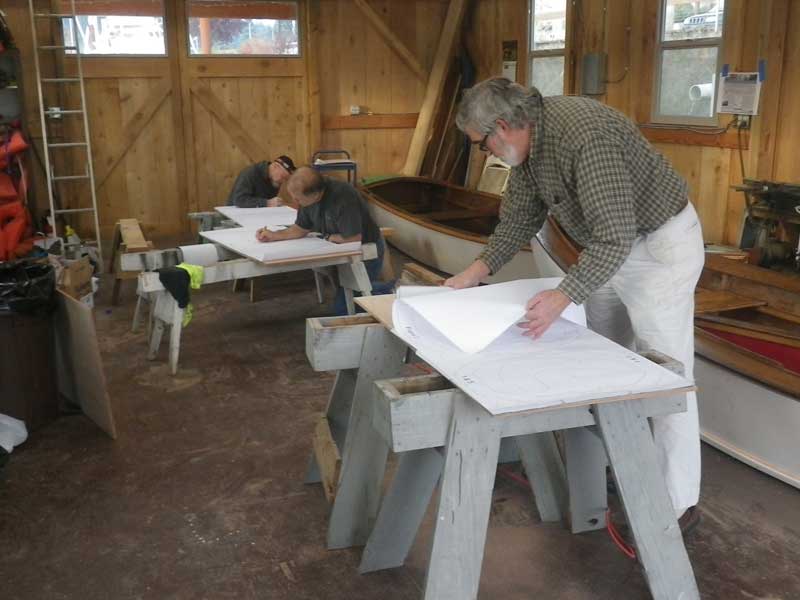

I'd had full sized patterns for the frames and stems printed up ahead of time and got enough carbon paper for everyone. We chopped up the 1/2" ply and got started tracing out the patterns.

Two stems and five frames per boat, each frame with 11 notches.

After tracing, it was time for cutting. Jim likes the bandsaw, but Curt and I went at it with Bosch sabersaws. Man, I've never used a high-end sabersaw before - that Bosch JS470E I got for the Boathouse is SWEET! And with the 20tpi blade, it's like cutting butter. Curt's Bosch 1590EVSL is even better. Christmas is coming and every boat builder needs a nice sabersaw. Tracing and cutting the frames took more than the time allotted, so we broke for the evening.

The next morning, I went out to Siletz River Lumber to find the sticks we'll need to make the wales, stringers and keel. Siletz River Lumber is well guarded, I don't recommend dropping by unannounced.

I was selecting cast-offs, mostly 16' sticks in the 1x2 or 2x2 range. I needed enough material to get (8) 3/4 x 1 1/2s for the wales, (24) 3/4 x 3/4s for the stringers, and (4) 3/4 x 1s for the keels (plus another 1x2 for the fiddy bits.) Curt helped me pull 'em, then tallied up the total.

I've heard in some countries, you need to hang a red flag off anything that overhangs your car by more than four feet. It's a good thing we have the War on Drugs to keep our police busy or I'd have gotten a ticket.

Back at the Boathouse, things started hopping. Rick and Aaron turned to on ripping the timbers while Curt got out a chisel and finished up knocking out the notches for the frames.

We got Frank set up on the router table where he rounded off the corners of the frames in preparation for sanding and oiling next week.

You know there's a lot to be done when even I get into the act. I was ripping up the 1/4" ply to make blanks that will become the floorboards. It was a fantastically busy session at the Boathouse this week. We had Depot Bay ringing with the sounds of industry. Best of all, we had a couple families stop by and watch us in action - they'd read the article in the New-Times and wanted to see the fun. Good work, everyone! I really appreciate all the help. This Family Boat Build is going to be great. |